Shaking table is one of the main gravity ore dressing equipment, which is widely used in the beneficiation of tungsten, tin, tantalum, niobium, gold and other rare metals and precious metal ore. It can be used for roughing, selection, scavenging and other different operations, so as to separate coarse sand, fine sand, mud and other different particle size materials. Shaking table can also be used to separate iron, manganese ore and coal. When processing tungsten and tin ore, the effective recycling granularity scope of shaking table is 2-0.22 mm.

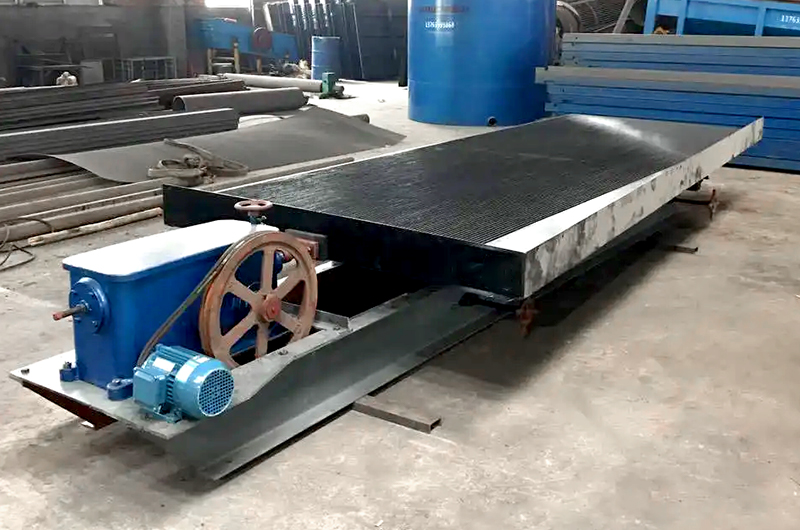

Shaking Table

Feed Size 0.15-2mm

Capacity 1-60/h

Exported Countries Sudan, United States, Turkey, Laos, United Kingdom, Brazil, United Arab Emirates, Indonesia, Mexico, South Africa, Tanzania, Botswana, Uganda, Cote d'Ivoire, etc.

Applied Materials Tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, silver, zinc, antimony, coal, heavy metal materials, and other metal ore materials, etc.